2.5 Ton Capacity Agro Machines for Sale Offered by Hmbt

Basic Info

Model No.: ZLG850

Product Description

Model NO.: ZLG850 Voltage: as Customer Required Controlling Mode: Artificial Certification: CE, ISO, SGS Customized: Customized Color: Multi Color Cetificate: CE,ISO,SGS Deliver Time: in Stock for Normal Type Capacity: 2.5~3 Ton Per Hour Bearings: Customized From China Famous Factory Dead Load: 14.2t Transport Package: Bubble Wrap, Iron Case or Steel Box Origin: China Type: Ring Die Vertical Pellet Mill Automatic Grade: Semiautomatic Energy Saving: Energy Saving Warranty: 1 Year Condition: New Machine Material: Thickened Steel Ensures Working Stable Main Power: 220 Kw Pellet Size: D=4~12mm Mold: Alloy Steel Outline Dimension: 3300*1400*3100 Mm Trademark: HMBT Specification: ISO9001, CE, SGS HS Code: 84834090 agro machines

pellet mill, also known as a pellet press, is a type of mill or machine press used to create pellets from powdered material. Pellet mills are unlike grinding mills, in that they combine small materials into a larger, homogeneous mass, rather than break large materials into smaller pieces.

Pelletizing or making pellets is the process of using organic material such as corn stalks, corn cobs, grass, leaves, bean stubble, switchgrass, straw, dry distillers grain (DDG), seed hulls, alfalfa, cardboard, saw dust and paper and putting them through a pellet mill to form pellets. These pellets are then used for burning as fuel in pellet stoves or furnaces or used as animal feed and animal bedding. There are multiple uses for pellets.

We offer flat die and ring die pellet mill for you to choose from according to your requirement.

The structure of flat die pellet mill

There are two parts of flat die pellet mill: driving parts and pelleting part.

Driving parts include motor, couplings and gear box;

The pelleting parts includes the main axis, and the granulating room. There are mould, pressure roller and the pellet cutting knife in granulating room.

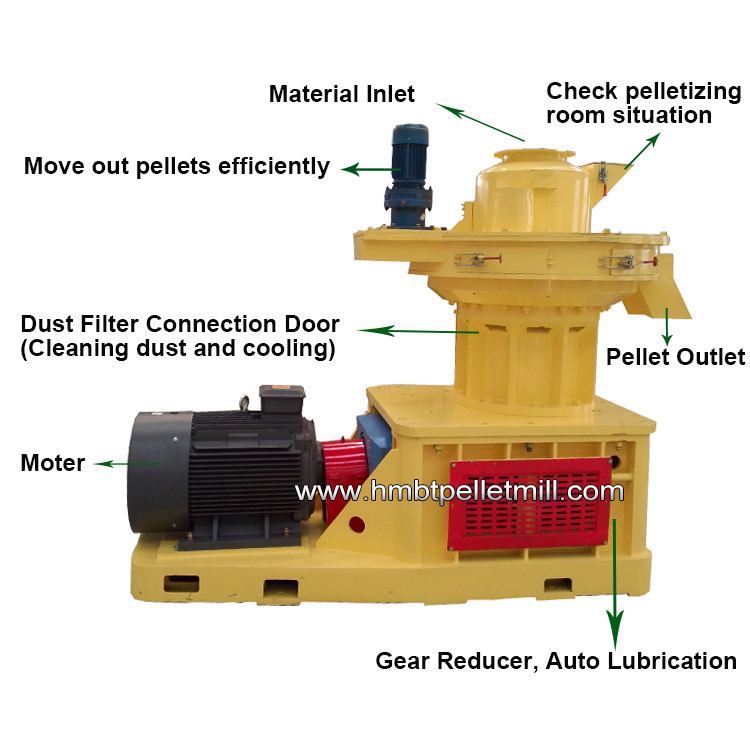

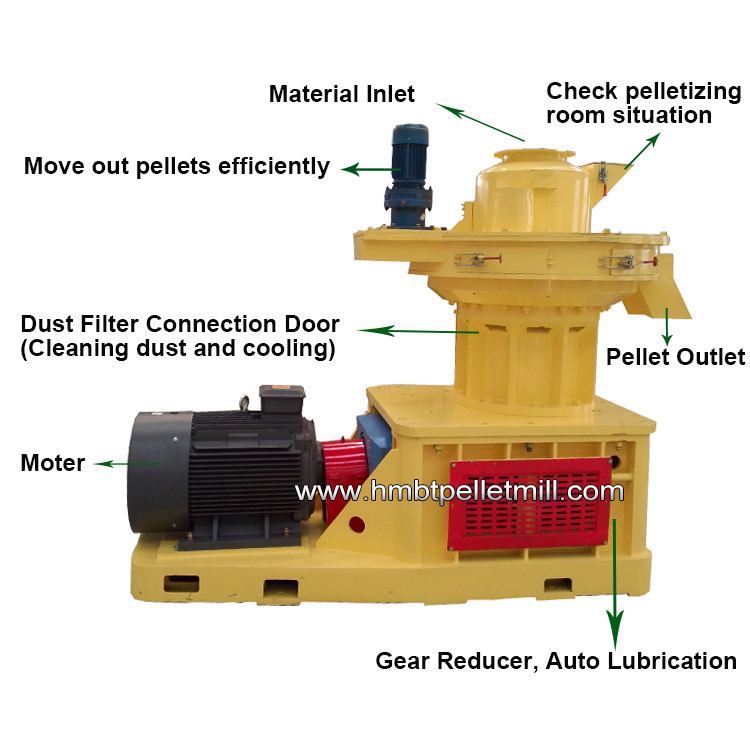

Ring die High efficient centrifugal pellet mill

Stuture of ring die pellet mill:

modulation section and main machine

The modulation sections has feeding machine, single modulation or double modulation

The main machine includes driving, main axis and the pelleting room(moud, pressure roller and cutting knife)

1. ring die pellet mils absorbs the essence of the granulating machine at home and abord,the heart part is "double stack mold", equipment structure is unique,and the pinch roller adopt high alloy wear-resistant material . Transmission structure oil automatic filtering . With unique design,reasonable structure, low efficiency, strong wear resistance,etc.

2. It is suitable for pressing hard , molding difficult materials, such as rice husk, shell of sunflower seed, peanut shells and so on various melon shell.Tree branch, tree trunk,tree bark and all kinds of wood scraps.All kinds of scrop straw,rubber,cement,ash and other chemical raw materials.

3. It applies to biomass fuels plant, power station, timber mill, fertilizer plant,chemical plant,etc.

The Working Principles to ZLG series efficient centrifugal pellet mill

ZLG series efficient centrifugal pellet mill is different from the other feed pellet mill's method of mold installation. Its mold is placed horizontally on the machine.

Materials go into the mold internal by the conveying device, and the wheel rotates with materials to produce centrifugal force, which throw materials evenly in inner wall of the mold. At the same time the wheels rotates to press the materials.

Through the forming hole, and after several press, pellets come out from the outer wall. After the cutting plate, pellets become uniform size.

Usage of ring die pellet mill----It is mainly sused for feedstuff insustry.

Wearing parts of ring die pellet mill mould (with pore diameter 2-8mm), roller skin, bearings and triangular belt.

advantages of ZLG series efficient centrifugal pellet mill as follows:

Vertical type, vertical feedstock, prevent die buildup efficiently.

Mould stationary, pinch roller rotating, make the material well-distributed, enhance productivity.

Double-deck mould, one machine dual use, one set mould can produce two kind of particle, which lower the cost efficiently.

Two set lubricating device, pinch roller automatic lubrication, gear case circulating lubrication, guarantee the machine smooth running for a long time.

Professional after-sale service team, on-site installation, phone guide installation.

tech data for our ring die pellet mill

FAQ

1. What's the delivery time?

We will deliver the product in 7-15 days after receiving the deposit.

2. What's your payment terms?

We can accept various payment terms if it is convenient for you.

3. Can you send the sample first?

We would be glad if you come to visit our factory and see the machine.

4. What's the lifetime of the wearing parts?

The material of our product is of high quality, and the lifetime of our wearing parts is twice longer than the others,including the roller skin, die and bearing.

5. What is your warranty?

12 months except the spare parts.

6. Are you a trading company or a mnufacture?

We are manufacturer since the year of 2003 in machinery producting line.

7. Will yousend engineers to install the plant?

Of course yes,but at an extra cost will be paid by customers. Or you can get local contractors to do the commissioning and we send one supervising engineer.

8. How can i get your company?

You can get a flight to Jinan Internatioal Airport, then have a short journey of 40-50 minutes's driving from the airport.

9. Do you have some foreign customers useing your equipments?

Yes , we have customers all over the world.

Our Services

----Providing timely delivery, standby engineers are ready to slove any of your problem in time.

----we provide one years warranty for the steel structure.

----Providing all-embraced warranty of products quality, worksite installation guidance

----Providing ample spare parts and training of operation and maintenance

----Engineers have more than 5 years' experience.

Contact us if you need more details on Pelletizing Machines. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Pellet Machine、Extruder. If these products fail to match your need, please contact us and we would like to provide relevant information.

pellet mill, also known as a pellet press, is a type of mill or machine press used to create pellets from powdered material. Pellet mills are unlike grinding mills, in that they combine small materials into a larger, homogeneous mass, rather than break large materials into smaller pieces.

Pelletizing or making pellets is the process of using organic material such as corn stalks, corn cobs, grass, leaves, bean stubble, switchgrass, straw, dry distillers grain (DDG), seed hulls, alfalfa, cardboard, saw dust and paper and putting them through a pellet mill to form pellets. These pellets are then used for burning as fuel in pellet stoves or furnaces or used as animal feed and animal bedding. There are multiple uses for pellets.

We offer flat die and ring die pellet mill for you to choose from according to your requirement.

The structure of flat die pellet mill

There are two parts of flat die pellet mill: driving parts and pelleting part.

Driving parts include motor, couplings and gear box;

The pelleting parts includes the main axis, and the granulating room. There are mould, pressure roller and the pellet cutting knife in granulating room.

Ring die High efficient centrifugal pellet mill

Stuture of ring die pellet mill:

modulation section and main machine

The modulation sections has feeding machine, single modulation or double modulation

The main machine includes driving, main axis and the pelleting room(moud, pressure roller and cutting knife)

1. ring die pellet mils absorbs the essence of the granulating machine at home and abord,the heart part is "double stack mold", equipment structure is unique,and the pinch roller adopt high alloy wear-resistant material . Transmission structure oil automatic filtering . With unique design,reasonable structure, low efficiency, strong wear resistance,etc.

2. It is suitable for pressing hard , molding difficult materials, such as rice husk, shell of sunflower seed, peanut shells and so on various melon shell.Tree branch, tree trunk,tree bark and all kinds of wood scraps.All kinds of scrop straw,rubber,cement,ash and other chemical raw materials.

3. It applies to biomass fuels plant, power station, timber mill, fertilizer plant,chemical plant,etc.

The Working Principles to ZLG series efficient centrifugal pellet mill

ZLG series efficient centrifugal pellet mill is different from the other feed pellet mill's method of mold installation. Its mold is placed horizontally on the machine.

Materials go into the mold internal by the conveying device, and the wheel rotates with materials to produce centrifugal force, which throw materials evenly in inner wall of the mold. At the same time the wheels rotates to press the materials.

Through the forming hole, and after several press, pellets come out from the outer wall. After the cutting plate, pellets become uniform size.

Usage of ring die pellet mill----It is mainly sused for feedstuff insustry.

Wearing parts of ring die pellet mill mould (with pore diameter 2-8mm), roller skin, bearings and triangular belt.

advantages of ZLG series efficient centrifugal pellet mill as follows:

Vertical type, vertical feedstock, prevent die buildup efficiently.

Mould stationary, pinch roller rotating, make the material well-distributed, enhance productivity.

Double-deck mould, one machine dual use, one set mould can produce two kind of particle, which lower the cost efficiently.

Two set lubricating device, pinch roller automatic lubrication, gear case circulating lubrication, guarantee the machine smooth running for a long time.

Professional after-sale service team, on-site installation, phone guide installation.

tech data for our ring die pellet mill

| type | power(kw) | capacity(T/H) | pellet dimension(mm) | outline dimension(mm) | dead load (t) |

| ZLG560 | 90 | 1~1.5 | Φ4-Φ12 | 2600×1300×2300 | 5.3 |

| ZLG720 | 160 | 1.5~2.5 | Φ4-Φ12 | 2900×1300×2400 | 9.5 |

| ZLG850 | 220 | 2.5~3 | Φ4-Φ12 | 3300×1400×3100 | 14.2 |

| ZLG920 | 315 | 3~ 4.5 | Φ4-Φ12 | 3800×1680×3400 | 18 |

| ZLG1050 | 315 | 4.5~6 | Φ4-Φ12 | 4800*2680*3900 | 24.3 |

| ZLG1250 | 550-660 | 7~8 | Φ4-Φ12 | 5200*2860*4100 | 48 |

FAQ

1. What's the delivery time?

We will deliver the product in 7-15 days after receiving the deposit.

2. What's your payment terms?

We can accept various payment terms if it is convenient for you.

3. Can you send the sample first?

We would be glad if you come to visit our factory and see the machine.

4. What's the lifetime of the wearing parts?

The material of our product is of high quality, and the lifetime of our wearing parts is twice longer than the others,including the roller skin, die and bearing.

5. What is your warranty?

12 months except the spare parts.

6. Are you a trading company or a mnufacture?

We are manufacturer since the year of 2003 in machinery producting line.

7. Will yousend engineers to install the plant?

Of course yes,but at an extra cost will be paid by customers. Or you can get local contractors to do the commissioning and we send one supervising engineer.

8. How can i get your company?

You can get a flight to Jinan Internatioal Airport, then have a short journey of 40-50 minutes's driving from the airport.

9. Do you have some foreign customers useing your equipments?

Yes , we have customers all over the world.

Our Services

----Providing timely delivery, standby engineers are ready to slove any of your problem in time.

----we provide one years warranty for the steel structure.

----Providing all-embraced warranty of products quality, worksite installation guidance

----Providing ample spare parts and training of operation and maintenance

----Engineers have more than 5 years' experience.

Contact us if you need more details on Pelletizing Machines. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Pellet Machine、Extruder. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Biomass Pellet Mill

Premium Related Products

Other Products

Hot Products

Sc200/200 Construction Building HoistQtk20 Fast Erection Tower Crane Construction Tower CraneQtg10 Inner Climbing Tower Crane, Mini Tower Crane6515 Construction Building Tower CraneHigh Quality China Factory Luffing Jib Tower CranesChina Construction Hoist Building Hoist Construction Elevator PriceSs100/100 1ton Double Cage Material Hoist for Construction10 Ton Top Kit Tower Crane of Low Price Tower CraneCrane Truck for Construction CraneChina Tavol Qtz250 7030 Ce ISO with 16t 70m Boom Topkit Crane TowerJaw Crusher400t/H Soil Cement Wet Mix PlantHzs 90 Stationary Concrete Batching Plant (90m3/h)Qlby-60 / 60tph Mobile Asphalt Batching PlantLb2000 Asphalt Mixing Plant35m3 Mobile Concrete Batching Plant (YHZS35)