Flat Die Pellet Machine with CE

Basic Info

Model No.: ZLPM250

Product Description

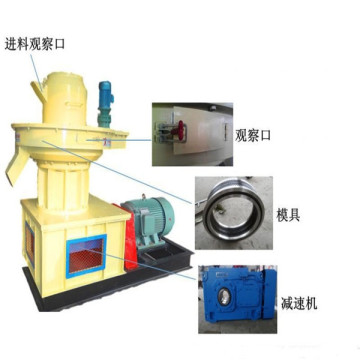

Model NO.: ZLPM250 Voltage: 380V Controlling Mode: CNC Certification: CE, ISO Customized: Customized Color: Multi Color Dimension(L*W*H): 900*400*100 Mm After-Sales Service Provided: Engineers Available to Service Machinery Overseas Use: Making Wood Pellets Pellet Length: 0.5-5cm Hole Diameter: 6, 8, 10mm Specification: CE HS Code: 84748020 Type: Flat Die Pellet Mould Automatic Grade: Semiautomatic Energy Saving: Energy Saving Warranty: 1 Year Condition: New Product Type: Feed Pellet Machine Weight: 200 Kg Mold: Wearable Alloy Steel Pellet Purity: >95% Main Material: Thickened Steel Ensures Working Stable Trademark: HMBT Origin: Jinan, China

Product introduction

Zlpm flat -die Pellet Mill adopts Germany carl pellet mill ,heart assembly unit "formwork"and "pinch roller"is avvordance with different material adopts wear-resistant material ,shares long service life.

Transmission part adopts automobile different mechanism ,cardan drive.with lower noise ,lower energy dissipation and higher efficient ,and easy to operation .which is developed by our company national initiative approved products.

The product is suit for feed mill ,cultivation factory and farmers.with little investment ,high effective and zero risks .this machine is ideal compact and compression molding equipment.

Characteristics

1.Wide adaptability, small occupation area,low noise.

2.Mash feed,grass power can granulation,so the moisture content of pellets is the water before pelleting material rate.

3.Dry machining,the production of feed particle have high hardness,smooth surface,internal curing,can improve digestion and absorption of nutrients.

The particle formation can make the grains,legumes trypsin resisting factor occur degeneration,reduce the adverse effects on the digestion.It can kill all kinds of parasite eggs and other pathogens,reduce all kinds of insects of digestive system.

Advantages

Use cold-pressing molding technology,polishing integer process.Streamline appearance,compact structure.

High output ,low consumption and noises,better stability and lower fault rates. Fatigue resistance is strong,continuous production,economy and durability.

Materials

Granular feed sources of raw materials , such as corn stalks, soybean straw , wheat straw , rice straw , flower seedlings ( shell ) , sweet potato vine , alfalfa , canola stalks and so on.Made after the forage particle density, high capacity,large capacity,conducive to long-distance transport ,realizes remote digestion and utilization of crop straw,so that the value of straw and rural incomes, agricultural development and to protect the ecological environment.Pellet feed through high temperature curing, pasting palatability, by farmers love,he people called it "the biscuit of cattle and sheep".Cattle and sheep feed rate can reach 100%,absorption rate can be increased by 60%,milk yield increased by 10% , beef cattle weight gain of more than 15 %.

Application

They are widely used in feed factories, breed aquatics factories, organic fertilizer factories, chemical factories, and China traditional medicine factories, etc, Certainly it is used as fuel to replaced coal. It can be used together with powder material. Its capacity is superior in the same industry home and abroad.

Feed pellet mill,is widely used in large,medium and small aquaculture,feed plant,animal farm,poultry farms, individual farmers,small and medium-sized farms and farmers or large,medium,small feed mills.

FAQ:

1. What's the delivery time?

We will deliver the product in 7-15 days after receiving the deposit.

2. What's your payment terms?

We can accept various payment terms if it is convenient for you.

3. Can you send the sample first?

We would like you come to visit our factory.

4. what's your MAQ?

Our MAQ is 1 set.

5. What's the lifetime of the wearing parts?

The material of our product is of high quality, and the lifetime of our wearing parts is twice longer than the others,including the roller skin, die and bearing.

6. What is your warranty?

12 months except the spare parts.

7. Are you a trading company or a mnufacture?

We are manufacturer since the year of 2001 in machinery producting line.

8. Will yousend engineers to install the plant?

Of course yes,but at an extra cost will be paid by customers. Or you can get local contractors to do the commissioning and we send one supervising engineer.

9. How can i get your company?

You can get a flight to Jinan Internatioal Airport, then have a short journey of 40-50 minutes's driving from the airport.

10. Do you have some foreign customers useing your equipments?

Yes , we have customers all over the world.

Wearing parts :

Wearing parts of ring die pellet mill: mould (with pore diameter 2-8mm), roller skin, bearings and triangular belt.

Our service:

----Providing timely delivery, standby engineers are ready to slove any of your problem in time;

----We provide one years warranty for the steel structure;

----Providing all-embraced warranty of products quality, worksite installation guidance;

----Providing ample spare parts and training of operation and maintenance all year long;

----Engineers have more than 10 years' experience.

Contact us if you need more details on Wood Pellet Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Flat Die Wood Pellet、Briquette Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product introduction

Zlpm flat -die Pellet Mill adopts Germany carl pellet mill ,heart assembly unit "formwork"and "pinch roller"is avvordance with different material adopts wear-resistant material ,shares long service life.

Transmission part adopts automobile different mechanism ,cardan drive.with lower noise ,lower energy dissipation and higher efficient ,and easy to operation .which is developed by our company national initiative approved products.

The product is suit for feed mill ,cultivation factory and farmers.with little investment ,high effective and zero risks .this machine is ideal compact and compression molding equipment.

Characteristics

1.Wide adaptability, small occupation area,low noise.

2.Mash feed,grass power can granulation,so the moisture content of pellets is the water before pelleting material rate.

3.Dry machining,the production of feed particle have high hardness,smooth surface,internal curing,can improve digestion and absorption of nutrients.

The particle formation can make the grains,legumes trypsin resisting factor occur degeneration,reduce the adverse effects on the digestion.It can kill all kinds of parasite eggs and other pathogens,reduce all kinds of insects of digestive system.

Advantages

Use cold-pressing molding technology,polishing integer process.Streamline appearance,compact structure.

High output ,low consumption and noises,better stability and lower fault rates. Fatigue resistance is strong,continuous production,economy and durability.

Materials

Granular feed sources of raw materials , such as corn stalks, soybean straw , wheat straw , rice straw , flower seedlings ( shell ) , sweet potato vine , alfalfa , canola stalks and so on.Made after the forage particle density, high capacity,large capacity,conducive to long-distance transport ,realizes remote digestion and utilization of crop straw,so that the value of straw and rural incomes, agricultural development and to protect the ecological environment.Pellet feed through high temperature curing, pasting palatability, by farmers love,he people called it "the biscuit of cattle and sheep".Cattle and sheep feed rate can reach 100%,absorption rate can be increased by 60%,milk yield increased by 10% , beef cattle weight gain of more than 15 %.

Application

They are widely used in feed factories, breed aquatics factories, organic fertilizer factories, chemical factories, and China traditional medicine factories, etc, Certainly it is used as fuel to replaced coal. It can be used together with powder material. Its capacity is superior in the same industry home and abroad.

Feed pellet mill,is widely used in large,medium and small aquaculture,feed plant,animal farm,poultry farms, individual farmers,small and medium-sized farms and farmers or large,medium,small feed mills.

| Model | ZLPM105 | ZLPM120 | ZLPM150 | ZLPM200 | ZLPM250 | ZLPM280 | ZLPM300 |

| Power(kw) | 2.2 | 3 | 7.5 | 11 | 15 | 22 | 30 |

| Yield(kg/h) | 60-100 | 70-100 | 100-300 | 300-500 | 400-700 | 500-800 | 600-1000 |

FAQ:

1. What's the delivery time?

We will deliver the product in 7-15 days after receiving the deposit.

2. What's your payment terms?

We can accept various payment terms if it is convenient for you.

3. Can you send the sample first?

We would like you come to visit our factory.

4. what's your MAQ?

Our MAQ is 1 set.

5. What's the lifetime of the wearing parts?

The material of our product is of high quality, and the lifetime of our wearing parts is twice longer than the others,including the roller skin, die and bearing.

6. What is your warranty?

12 months except the spare parts.

7. Are you a trading company or a mnufacture?

We are manufacturer since the year of 2001 in machinery producting line.

8. Will yousend engineers to install the plant?

Of course yes,but at an extra cost will be paid by customers. Or you can get local contractors to do the commissioning and we send one supervising engineer.

9. How can i get your company?

You can get a flight to Jinan Internatioal Airport, then have a short journey of 40-50 minutes's driving from the airport.

10. Do you have some foreign customers useing your equipments?

Yes , we have customers all over the world.

Wearing parts :

Wearing parts of ring die pellet mill: mould (with pore diameter 2-8mm), roller skin, bearings and triangular belt.

Our service:

----Providing timely delivery, standby engineers are ready to slove any of your problem in time;

----We provide one years warranty for the steel structure;

----Providing all-embraced warranty of products quality, worksite installation guidance;

----Providing ample spare parts and training of operation and maintenance all year long;

----Engineers have more than 10 years' experience.

Contact us if you need more details on Wood Pellet Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Flat Die Wood Pellet、Briquette Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Biomass Pellet Mill

Premium Related Products

Other Products

Hot Products

Sc200/200 Construction Building HoistQtk20 Fast Erection Tower Crane Construction Tower CraneQtg10 Inner Climbing Tower Crane, Mini Tower Crane6515 Construction Building Tower CraneHigh Quality China Factory Luffing Jib Tower CranesChina Construction Hoist Building Hoist Construction Elevator PriceSs100/100 1ton Double Cage Material Hoist for Construction10 Ton Top Kit Tower Crane of Low Price Tower CraneCrane Truck for Construction CraneChina Tavol Qtz250 7030 Ce ISO with 16t 70m Boom Topkit Crane TowerJaw Crusher400t/H Soil Cement Wet Mix PlantHzs 90 Stationary Concrete Batching Plant (90m3/h)Qlby-60 / 60tph Mobile Asphalt Batching PlantLb2000 Asphalt Mixing Plant35m3 Mobile Concrete Batching Plant (YHZS35)